| Sign In | Join Free | My isp.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My isp.org.cn |

|

Brand Name : Eternal Bliss

Model Number : EB20015

Certification : ISO9001:2008

Place of Origin : China

MOQ : 1ton

Payment Terms : L/C, T/T,, Western Union

Packaging Details : Plywood Case: 1500 x 1000 x 1000mm (Max.) 20 feet container: 25 tons (Max.)

Material : Co-base Alloy

Standard : 316L,304,321

Service : OEM ODM Service

Surface treatment : Sand Blasting

Process : Casting. Deburring .Drilling .threading

Application : Corrosion resistant

Heat Treatment : Solution

Stainless Steel Alloy Internal Liner for Seat Valve Body with Full Machining EB200015

| Heat Resistant Castings | Heat-Treatment Fixture | Wear Resistance Castings | Cement Mill Liner |

| Radiant Tube | Coal Mill Liner | ||

| Furnace Roller | Mine Mill Liner | ||

| Cooler Plates For Cement Plant | High Cr Casting | ||

| Spray Nozzles | Ni-Hard Casting | ||

| Melting Pot Castings | Cr-Mo Alloy Steel Casting | ||

| Slag Pot Castings | High Mn Steel Casting | ||

| Featured Product | Centrifugal Castings | Wear-Resistant Steel Plate | |

| Bolts For Mills & Crushers | Chute Liner | ||

| Al & Copper Forgings | Ball Mill Lining Sag Mill Lining | ||

| High Alloy Forgings | Crusher Wear Parts | ||

| Ductile & Gray Iron Castings | Corrosion Resistant Castings | Cobalt Alloy Castings | |

| Special Alloy Surface Coating & Overlay Weldings | Ni Alloy Castings | ||

| Heat-Treatment Furnaces | Stainless Steel Alloy | ||

| Drilling Rigs | Non-Ferrous Alloy (Al & Cu) |

| Trade Terms | FOB,EXW,CIF |

| Port | Shanghai |

| Shipment | By sea,by express or by air |

| Payment Terms | L/C,TT,Paypal,West Union |

| Payment Condition | 30% before production, 70% before delivery |

| Supply Capability | 10,000 tons per year |

| Sample Availability | Yes |

| Sample Time | 15-30 Days |

| Packing | Plywood Cases or Steel Crates |

| Delivery time | 45 days per 20 tons regular casting products |

| Service | OEM, ODM or Customized |

A: We are factory.

A: Generally it is 5~10 days if the goods are in stock.Or it is 45 days if the goods are not in stock, it is according to quantity.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment

![]()

Material Grade: Stainless Steel,Alloy Steel, Non-magnetic Steel, Carbon Steel,Non-ferrous

Production Process:Cast Process,Open Die Forging Process

Section Thickness: Up to 200mm;

Length max.: 3500mm.

Product Types: Step shaft forgings,excentric shaft,roller forgings,rod and bar blank forgings,valve body forging,gear wheel forgings, gear rings,vehicle wheel forgings,oil cylinder forgings,offset axis.

Unit Weight: 20kg ~ 50000kg.

Production Facilities:

Induction Melting Furnaces

Electric-hydraulic hammers with capacity 8 tons,6 tons,3 tons;

Feeding Machines with capacity 10 tons, 5 ton;

Heat-treatment Furnaces: 5 sets;

Disc Type Band Saws: 6 sets;

Machining Facilities: 3 sets.

Annual Capacity with Open Die Forging Process: 30,000tons.

Chemocal Composition:

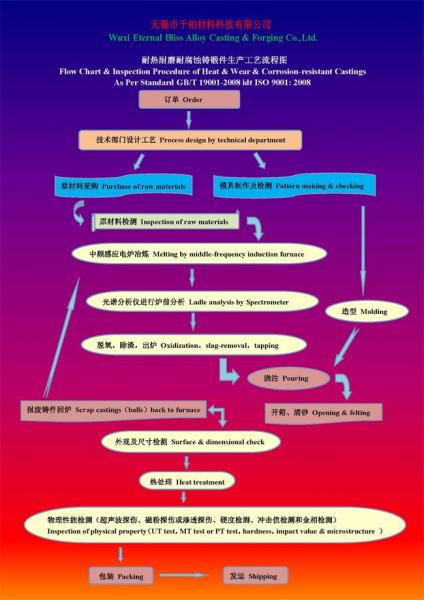

Production Process

Step 1: Getting orders.

Step 2: Process design by technical department

Step 3: Purchase of raw materials and pattern making &checking

Step 4: Inspection of raw materials

Step 5: Melting by middle-frequency induction furnaces

Step 6: Ladle analysis by Spectrometer

Step 7: De-oxidization, slag-removal, tapping

Step 8: Pouring

Step 9: Openning & fettling

Step 10: Surface & dimensional check

Step 11: Heat treatment

Step 12: Inspection of physical property (UT test,MT test, hardness,impact value µstructure)

Step 13: Packing

Step 14: Shipping

![]()

1. 18-year Foundry Operation Experience.

2. Friendly & High Efficient Technical & Commercial Communication.

3. Professional Export Practices: Have Exported to +60 Overseas Countries.

Our Trade Show

Our booth No. 14-A29-5 in Newcast 2015,Germany

Hall 14, Stand No.A29-5.

Contact Us for further information about products & service:

|

|

Seat Valve Body Stainless Steel Alloy Anti Corrosion With Full Machining EB20015 Images |